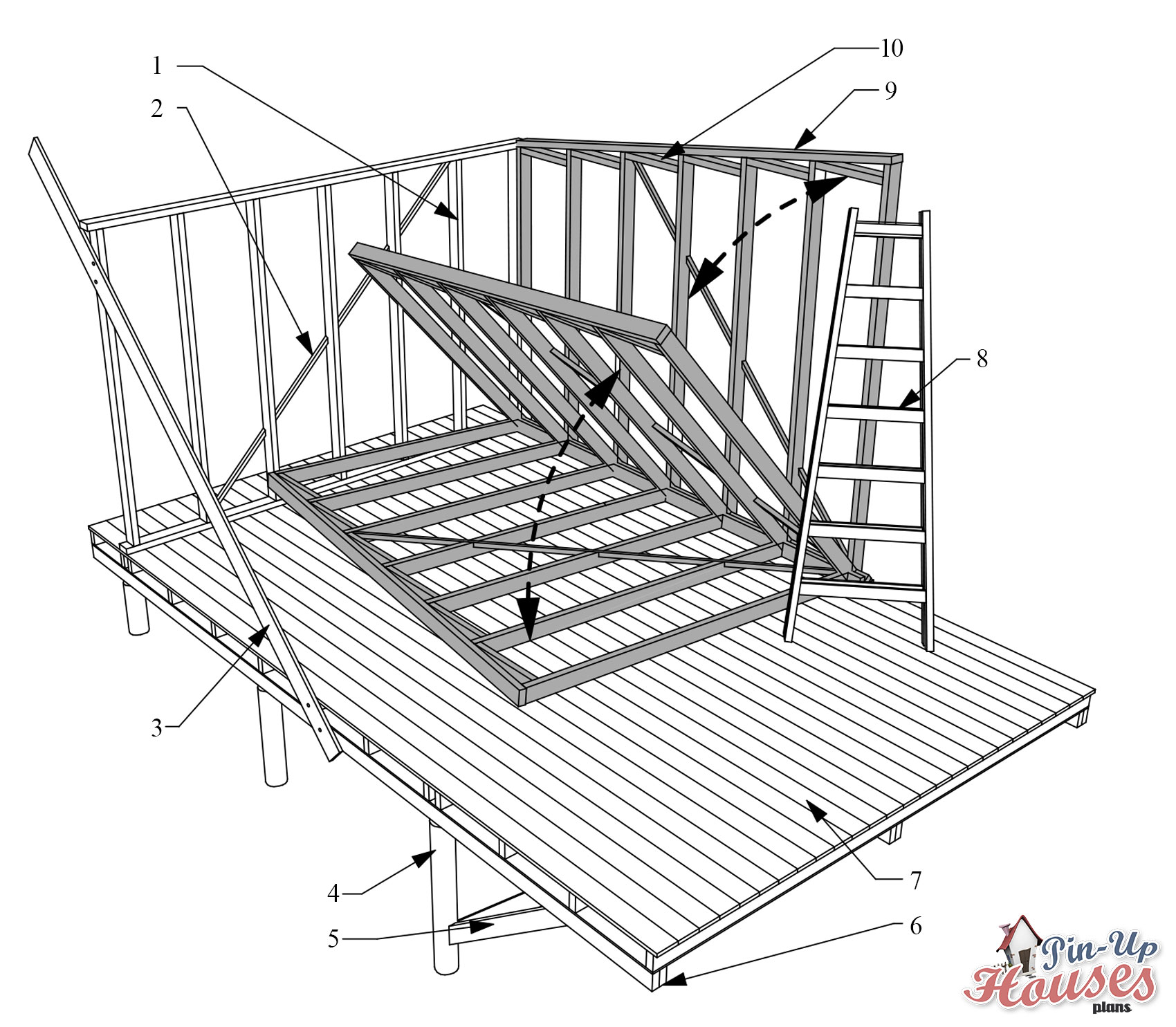

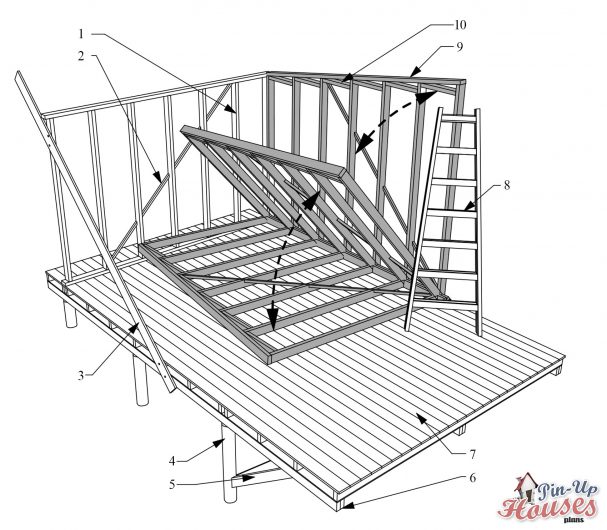

Assembling walls

For assembly of the walls of wooden tiny house construction, the two by four type structural timber is usually used, especially for the one-story buildings where walls do not need to support the load of levels above. The principle of building these wood-frame structures is rapid. Thanks to the favorable weights of the structures, there is no need for heavy lifting machinery. All of the work can be done by human force. If the foundations and floor structure are ready, the assembly of individual walls can commence.

It is recommended to have all the components cut and ready first. A solid wooden board may provide an even surface for the individual wall parts to be assembled, following the building project documentations. The finished walls are erected and anchored to the floor; then, they are screwed together. This is done until all the walls of the first floor have been completed.

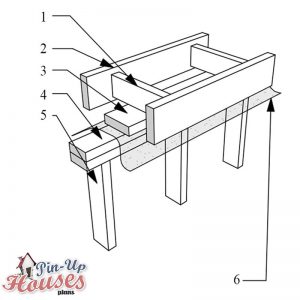

- wall pillars

- bracing

- temporary support (bracing)

- footing pillars

- the strap (bracing)

- combined joists

- floorboard

- ladder

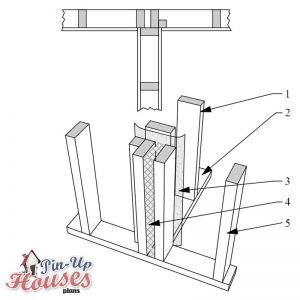

- upper plate

- nogging

The wall structure consists of several wall components, among the main ones are horizontal plates, vertical studs, interior deck, bracing, breathable membrane keeping interior moisture away from other layers of insulation, thermal insulation protecting the interior environment, sheathing, which also acts as bracing, battens securing various layers of the wall, rainscreen preventing the moisture from the outside leaking into the wall, exterior cladding against the weather conditions effects and installations.

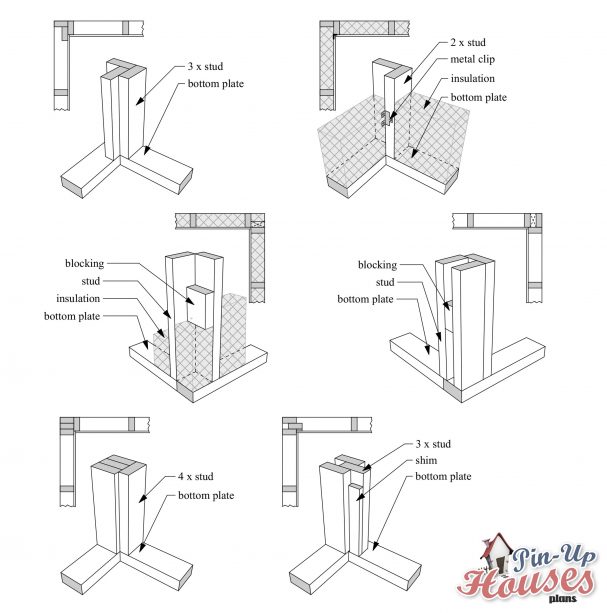

Corner framing / Multiple studs

There are many ways of tackling the connection of two walls at a corner. If the connection is to be as strong as possible, multiple studs’ option should be chosen. You can also use short blocks between the studs to further strengthen the corner posts. However, there is usually more of a thermal bridge, and more material is needed.

Non-load-bearing walls – Stud walls construction

Besides the strength of the connection, the contact between two walls emphasizes the elimination of thermal bridges and the separation of the structures through a separating layer – vapour barrier. There are many ways to proceed with building partition walls, and for all of them, it is essential to work precisely and make sure all the dimensions and leveling are correct. Otherwise, the whole wall could be week and prone to flex, and there would be a risk of complication later on when fixing the wallboard or installing doors.

Ways of partition wall connections:

- blocking nailed to ceiling joists

- ceiling joists

- nailing support

- plate

- stud

- partition stud

- bottom plate

- polyethylene strip

- insulation in spaces

- outer wall stud

- outer wall stud

- blocking

- bottom plate

- partition stud

- outer wall stud

- interior paneling

- partition stud

- bottom plate

Bracing and insulation

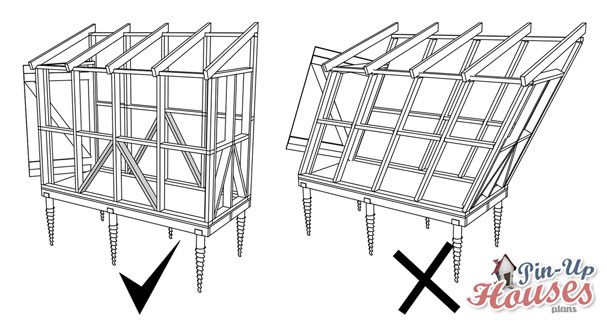

Bracing is one of the crucial parts of wall construction, preventing the construction from deformation or collapse caused by lateral forces. It is fixed diagonally to the vertical load-bearing components at an ideal angle between 45° and 60°, as too acute or obtuse angle would make the bracing ineffective. The most used bracing types are either a diagonal blocking made of the same material as the structural framework or a perforated wind bracing strap, which is placed on top of the load-bearing frame and nailed or screwed to it. Such straps made of wood are most common, for example, in the traditional roofs where the attic space is about to be inhabited. Also, another type of wind bracing is made of OSB or plywood boards with the advantage of helping to make the building’s corners more rigid as well.

Another important part of the wall is thermal insulation, maintaining a comfortable environment inside the building regardless of weather and temperature. Today, several materials are used: mineral insulation (rock wool), natural or synthetic (polystyrene). The load-bearing wall frame is usually installed after the installations such as water, sewage, etc., are in place and just before putting the final internal wall finishes. The thermal installation is also placed in the roof, between the individual rafters, and in the floor between the joists.

Small house construction process book

Are you interested in additional information related to small house construction? Check out my new book How to build a tiny house, where you can find plenty of practical tips and instructions related to the tiny house movement!